About Technical Services & Business Development

The Technical Services and Business Systems Department has several important functions within Hwange Colliery Company Limited. The purpose of the Department is to identify , define and schedule areas where coal resources and related products will be extracted in order to maintain the HCCL foot print as a reliable and consistent supplier to the market for the next generation and beyond in a sustainable and safe manner. The Department includes the following disciplines: SHEQ, Geology, Quality Assurance, Survey and Mine Planning.

Purpose

Sections

Team

Technical Services & Business Development Manager

Head of Technical Services & Business Development. The Department consists of 5 sections including the following:

- Geology

- Mine Planning

- Quality Assurance

- SHEQ

- Survey

Chief Geologist

SHEQ Manager

Chief Surveyor

SHEQ

.

Quality Assurance

.

Sections

Geology

Lubimbi special grants extensions was granted in September 2020.Concluding the Lubimbi EIA and applying for a mining special grant.

Services

Projects

Geology

Geology

Geology

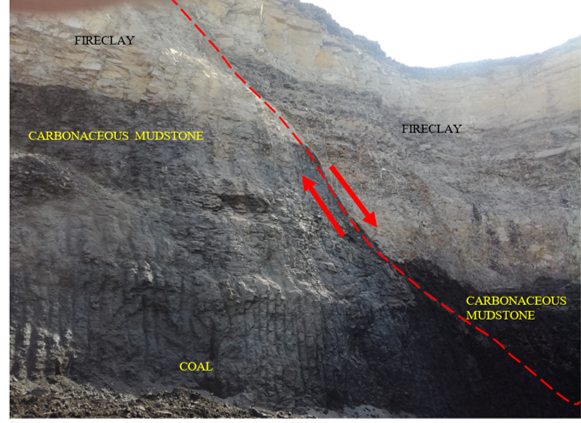

Surface Mapping

Mapping at JKL-listric normal fault

Geologist going to conduct underground mapping

Geology team assisting in the Geophysical

mapping project at Ramp 7 East.

Survey

Services

Survey

Survey

(Opencast-JKL)

(Surface & Underground)

Surpac Software Training

Quality Assurance

Services

Sulphur Analyser

Water Analysis

Ultimate Analysis using XRF Spectrometer

Ash Furnace

Pellet Making

SHEQ

Dedicated to ensuring effective management of the significant SHEQ Risks in order to fulfil the HCCL vision of zero harm to people and the environment. Responsible for establishing appropriate IBMS Policies and setting targets, which the entire organisation must then implement. Maintenance of IBMS through ISO Tri-certification [ISO9001:2015; ISO14001:2015 & ISO45001:2018]

Services

Corporate Social Responsibility

Management

School awareness session on community hazards.

Department Documents

Production Geology Procedure TSBDP 2.01

Production Geology Work Instruction GEOLWI 3.02

Rock Mechanics Geology Work Instruction GEOLWI 3.04

Surveying Procedure No TSBDP 2.02

Safe handling, transportation, storage, use and maintenance of equipment.

This procedure describes the transportation, receipt, handling, protection, storage, retention and disposal of test items. It also covers integrity of test items.

Sampling from different points to ensure unbiased samples that represent the population.

This procedure describes the steps taken in handling of training to improve Laboratory employee skills and knowledge.

Quality Control activities undertaken to ascertain validity of tests and calibrations.

This procedure describes the steps taken when reporting laboratory analytical results

This procedure describes the selection, safe handling, storage, checking and use of Reference Materials.

The Purpose of this Procedure is to keep the Laboratory neat and tidy

Steps taken in the event of an emergency at the Central laboratory.

Chemical Handling Procedure

Caking index determination for Coking coals

% Ash in coal and coke

FSI of coal

Wet Phosphorus method

Micum test

Determination of VM

Float and Sink analysis

pH determination in coal

Determination of inherent moisture

Sizing analysis

Determination of free Moisture in Magnetite

Magnetite Loss

Size analysis of Magnetite

Determination of percentage Magnetite

Stonedust compliance

% Incombustibles in stonedust

Determination of Ammonia in water

Calcium hardness in water

Determination of Conductivity in water

Determination of Iron in water

Determination of Manganese in water

Determination of Sulphates by gravimetry

Determination of Nitrates in effluent water

pH determination in water

Determination of Phosphates

Determination of Fluorides

Determination of Total Dissolved Solids in water

Determination of Total Hardness in water

Determination of residual Chlorine in water

Borehole sample preparation

The procedure details the management of COVID -19 cases in the workstation

The procedure highlights how emergencies within the organisation should be addressed.

To provide guidance on the identification and assessment of potential emergencies, documentation and communication of response needs.

To ensure appropriate and adequate personal protective clothing/equipment is provided, maintained and effectively applied as part of an overall risk management strategy.

To ensure management of all forms of effluent water generated from Hwange Colliery Company Limited activities and services.

To outline general guidelines on various IBMS meetings in different IBMS Committees.

To ensure management of all forms of waste generated from Hwange Colliery Company Limited activities and services.

Global procedure for HCCL Hazardous Substances

Training and awareness

This procedure describes how dust, noise, air quality and illumination measurements are carried out and reported.

To describe how incidents are reported and investigated with the aim of developing corrective and preventive action plans to avoid recurrence of similar incidents.